08 Jan What is the Difference Between a Sanitary Tee and a Wye?

When installing drainage, waste, and vent (DWV) piping systems, two types of fittings you’ll commonly encounter are sanitary tees and wyes. While they may look somewhat similar at first glance, some important differences between these two fittings determine when and where each one can be used. In this comprehensive guide, we’ll explore what is the difference between a sanitary tee and a Wye, how they function, where they are installed, and the key differences that set them apart. Whether you’re a homeowner trying to decipher your property’s plumbing or a professional installer looking to brush up on code requirements, read on to learn the ins and outs of these two critical drainage fittings.

What is a Sanitary Tee Fitting?

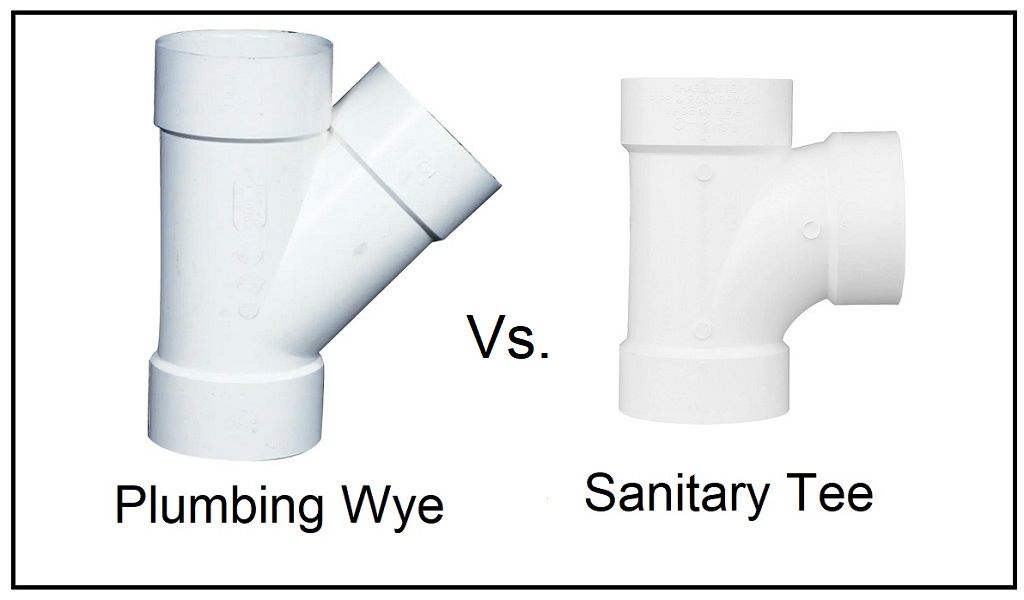

A sanitary tee is a fitting used to connect horizontal and vertical runs of drainage piping. It’s a three-way fitting that looks like the letter “T”, with one opening on the run side and two openings on either end of the branch side.

The key feature of a sanitary tee is that it has a curving sweep on the interior radius of the branch connection. This curved section promotes smooth drainage flow and helps prevent buildup or clogging within the fitting. The ends of a sanitary tee are also specially designed to accept fittings at up to 45 degree angles.

Sanitary tees allow drainage pipes to be routed horizontally and then redirected vertically, such as extending a drain line from a bathroom vanity up towards the ceiling and main stack. They are commonly installed in drain, waste, and vent systems to connect fixtures to vertical stacks.

Some key facts about sanitary tees:

- Made of cast iron, PVC, ABS, or other DWV-approved materials

- Have a swept branch with no interior ledges or gaps

- Allow a smooth transition from horizontal to vertical

- End connections accept up to 45 degree fittings

- Used to connect drainage piping only (not pressure piping)

What is a Wye Fitting?

A wye fitting is another important three-way connector used in drainage systems. It also joins together one horizontal opening (the run) and two vertical or angled openings (the branches).

However, wye fittings have some noticeable differences from sanitary tees. Most significantly, they have a flat interior radius where the branch connections meet the run. This forms a 90 degree interior angle rather than a swept bend. The ends of a wye also typically only accept fittings inserted straight on, not at an angle.

Wye fittings offer distinct advantages when it comes to accommodating gradual cleanout brancqhes compared to directly connecting horizontal fixture drains. The key lies in their design features, which facilitate the vertical routing of piping for vent stacks, cleanouts, or drainage branches that extend outside the main flow path. This versatility makes wye fittings a preferred choice over sanitary tees in situations where the emphasis is on creating efficient and effective plumbing systems. The decision between sanitary tee vs wye depends on the specific requirements of the plumbing layout and the need for seamless integration of cleanout branches within the overall design.

Some key facts about wye fittings:

- Made of cast iron, PVC, ABS, or other approved materials

- Have a flat interior radius at branch connections

- End connections are straight, not angled

- Used for vent stacks, cleanouts, and drainage branches

- Not approved for tight horizontal-to-vertical drainage transitions

Now that we’ve covered the basics, let’s look closer at how sanitary tees and wyes differ in their specifications and approved uses.

Key Differences Between Sanitary Tees and Wyes

While sanitary tees and wye fittings are both critical components in DWV systems, there are some important distinctions between the two:

Interior Radius

- Sanitary Tees: Have a curving, swept interior radius to promote smooth drainage flow.

- Wyes: Have a flat, 90 degree interior radius at branch connections.

End Connections

- Sanitary Tees: End connections are made to accept fittings at up to 45 degree angles.

- Wyes: End connections are made for straight fittings only, not angled ones.

Main Drainage Connections

- Sanitary Tees: Approved for tight horizontal-to-vertical drainage transitions.

- Wyes: Not approved for directly connecting horizontal drains to vertical stacks.

Branch Connections

- Sanitary Tees: Branches can serve as drain or vent connections.

- Wyes: Branches are primarily used for vents, cleanouts, and minor drainage lines.

Flow Characteristics

- Sanitary Tees: Swept branches promote smooth, optimized drainage flow.

- Wyes: Flat interior radius can impede drainage flow if installed in tight bends.

Clog Potential

- Sanitary Tees: Low clog potential due to smooth interior contours.

- Wyes: Moderate clog potential if used on tight horizontal-to-vertical transitions.

By keeping these key differences in mind, we can start to understand when one fitting is preferred over the other. Next we’ll look at how sanitary tees and wyes are installed and used within drainage systems.

Where are Sanitary Tees Installed?

Sanitary tees are installed to connect horizontal drainage piping to vertical stacks and branches. Their swept design allows them to transition from horizontal to vertical without impeding the flow of waste.

Some common sanitary tee applications include:

Connecting Fixture Drains to Stacks

One of the most common uses for a sanitary tee is connecting the drain piping from a plumbing fixture, such as a sink, toilet, or bathtub, to the vertical stack it drains into. The sanitary tee allows waste to smoothly flow from the horizontal fixture drain up into the stack.

Combination Waste and Vent

Sanitary tees can also connect the drains for bathroom sink groups into a combination waste and vent pipe. The vertical branch of the tee serves as both a drain and vent for the fixtures.

Drainage Branches

Sanitary tees may also be installed on their side to create a drainage branch line. This allows additional fixtures to be tied in horizontally from a stack.

Stack Connections

Sanitary tees join smaller vertical stacks together as they converge into larger and larger pipes on their way to the main sewer line.

In all these cases, the sanitary tee’s swept design maintains free and optimized drainage flow.

Where are Wye Fittings Installed?

While sanitary tees are used for tight horizontal-to-vertical drainage connections, wye fittings have other important roles in DWV systems:

Vent Connections

One very common use for wye fittings is to connect vent stacks that run vertically to provide proper airflow for drainage lines. The wye allows a vent to be branched off a drainage line while maintaining a straight interior contour.

Drainage Branches

Wyes are well suited for branching less trafficked drainage lines off of main stacks. This avoids impeding the flow in primary drain lines.

Cleanouts

Installing wyes on their side provides easy access for rodding and clearing clogged drains via a cleanout. The straight-on branches are ideal for cleanout connections.

Reducing Branches

A wye with reducing bushings allows for an intentional reduction in pipe size on a branch run.

Tight Bends

In some cases, wyes can also be used on tight horizontal-to-vertical turns as an alternative to a sanitary tee. However, this is generally not advisable as it can create flow restriction and clogging issues.

Sanitary Tee vs Wye: When to Use Each Fitting

When deciding between a sanitary tee and a wye, the most important factor is the type of connection being made:

Sanitary Tees are best for:

- Tight horizontal-to-vertical drainage transitions

- Directly connecting fixture drains to stacks

- Any applications where optimized drainage flow is critical

Wye Fittings are best for:

- Vent connections

- Optional and secondary drainage branches

- Cleanouts and rodding access

- Gradual drainage bends (but not tight ones)

Additionally, sanitary tees can only be used for drainage lines, as their swept connections are not suitable for pressure applications. Wyes, in contrast, are approved for some pressure connections when the proper types of ends are used.

The following comparison chart summarizes when each fitting is recommended and required by code:

| Application | Sanitary Tee | Wye |

| Tight horizontal-to-vertical drainage transition | Required | Not allowed |

| Connecting fixture drain to stack | Required | Not allowed |

| Combination waste and vent | Required | Not allowed |

| Main or primary drainage branch | Required | Allowed |

| Secondary drainage branch | Allowed | Required |

| Vent connection | Not allowed | Required |

| Cleanout connection | Allowed | Required |

| Reducing branch | Not recommended | Required |

| Pressurized water connections | Not allowed | Allowed with proper ends |

Sanitary Tee and Wye Installation Tips

When installing sanitary tees or wyes, here are some best practices to follow:

- Maintain a smooth, gradual slope on horizontal runs leading into the fitting

- Keep vertical stacks as straight as possible; avoid unnecessary bends

- Support pipes properly with hangers to prevent sagging and maintain slope

- Align fittings carefully; misaligned connections can cause blockages

- Always use approved pipe adhesives, primers, and sealants

- When using PVC or ABS, follow proper solvent welding procedures

- Ensure fittings meet code requirements for the type of drainage system

- Avoid excessive use of fittings; minimize turns whenever possible

- Consider cleanout locations to allow access if clogs develop

Sanitary Tee and Wye Code Requirements

Sanitary tees and wyes must adhere to the specifications and limitations spelled out in the applicable plumbing code, such as:

- IPC – International Plumbing Code

- UPC – Uniform Plumbing Code

- Local city, county, or state amendments to the model codes

Relevant code sections cover material standards, sizes, slopes, approved usage, and installation methods. Key requirements include:

- Approved materials only (cast iron, PVC, ABS, etc.)

- Maximum distance between cleanouts

- Minimum and maximum drainage pipe slopes

- Proper support spacing for drainage pipes

- Limitations on change of direction fittings

- Approved solvents and primers for solvent welding

Always check with local codes before selecting and installing sanitary tees or wyes. Using unapproved or banned fittings could compromise drain system safety and performance.

Troubleshooting Sanitary Tee and Wye Problems

If clogs, leaks, or odors develop in a DWV system, potential causes relating to sanitary tees or wyes include:

Clogs:

- Using a wye on a tight horizontal-to-vertical bend

- Excessive turns or misaligned fittings disrupting flow

- Sagging pipes that create low spots for debris collection

- Undersized drain lines

Leaks:

- Cracked or damaged fittings

- Failed joints or loose connections

- Misaligned or poorly fitted connections

Odors:

- Drying out of water seals due to lack of use or evaporation

- Improperly installed or missing vent preventing air circulation

- Clog forcing sewer gases out through drains or fittings

In many cases, a visual inspection and some disassembly may be needed to locate the source of the problem. Replacing defective fittings, tightening connections, and clearing obstructions can resolve common issues. However, some drainage problems require re-piping to correct underlying design flaws.

Choosing the Right Sanitary Tee or Wye

When purchasing sanitary tees or wyes, always look for fittings approved for DWV systems. Avoid non-approved varieties like 90 degree elbows. Key considerations include:

- Material: Cast iron, PVC, ABS, etc. Make sure the fitting material matches the piping type.

- Diameter: Match the pipe size; reducing bushings can be used if needed.

- Connections: Match the joint types used in the piping system.

- Approvals: Look for markings indicating approval for DWV use. IAPMO and NSF stamps are common.

For mission-critical drainage connections, rely on tried-and-true brands and manufacturers that specialize in DWV components. Avoid no-name fittings of questionable quality. Consulting the manufacturer’s specs can also help verify proper applications and installation.

Sanitary Tee and Wye Safety Tips

DWV systems handle dangerous sewage gases and contaminants. Take proper precautions when working on sanitary tees or wyes:

- Wear eye protection when cutting or solvent welding pipes

- Use heavy work gloves when handling cast iron fittings

- Support piping properly so pieces don’t fall during assembly

- When possible, pre-assemble fittings at ground level before lifting

- Keep fire and spark sources away from solvent glues and primers

- Prevent solvent cement from contacting skin; wear gloves and eye protection

- Ensure work areas are well-ventilated

- Seal openings with plugs or caps when leaving work incomplete

Key Takeaways – Sanitary Tees vs. Wyes

- Sanitary tees have swept interior branches; wyes have flat branches

- Sanitary tees connect drains to stacks; wyes connect vents and branches

- Only sanitary tees can be used for tight horizontal-to-vertical transitions

- Wyes are required for vent connections; sanitary tees are not approved

- Both fittings must meet code requirements for proper DWV installation

- Select the right fitting for the connection type to optimize drainage

- Take safety precautions when working with solvents and sewer gases

With this understanding of sanitary tees versus wyes, you can now confidently install and inspect these critical DWV fittings. Proper selection and placement will prevent problems, ensure adequate drainage, and keep plumbing systems operating safely.

Frequently Asked Questions

Can I use a wye on its back instead of a sanitary tee?

This is generally not advisable. While a wye on its back may work in some cases, it does not provide an optimum swept radius for drainage flow. For proper flow and minimum clogging, sanitary tees should be used for tight horizontal-to-vertical transitions as required by code.

What is a double sanitary tee?

A double sanitary tee has sanitary tee configurations on both the horizontal and vertical planes, allowing for drainage connections in four possible directions. It can receive flow through either tee opening and redirect it out the other two.

Are sanitary tees and wyes interchangeable?

Most of the time, no. Sanitary tees and wyes have specific approved uses in a drainage system. Replacing one with the other in prohibited situations can impede drainage and venting or violate code.

Can I use a sanitary tee on the vent stack?

No. Because they have swept connections, sanitary tees are only approved on the drainage side, not for venting purposes. For vent stacks, wye fittings must be used instead.

What if I installed a wye where a sanitary tee was required?

If a wye was mistakenly used to make a tight horizontal-to-vertical drainage transition, it should be replaced with a proper sanitary tee fitting. The flat wye intersection could otherwise create flow problems and clogging issues.

Conclusion

Knowing when to use sanitary tees versus wye fittings is an essential skill for planning, installing, and troubleshooting DWV systems. While they may appear interchangeable at first glance, these two fittings have important differences in their specifications, approved uses, and installation requirements.

When faced with a sluggish toilet, implementing effective measures becomes crucial; adhering to code guidelines, such as using sanitary tees for critical drainage connections and reserving wyes for branches and vents, ensures that drainage and venting operate as designed, facilitating a swift resolution to the issue.

By understanding where to properly apply each type of fitting, plumbers can optimize system drainage, reduce the risk of clogs and leaks, and ensure that waste safely flows away as intended. With the central drainage network functioning properly, the comfort, health, and safety of the building occupants can be maintained.